Unravelling the Expensive Nature of Palm Leaf Plate Manufacturers in the USA: What Factors Contribute to the Higher Cost

Introduction:

The Cost Conundrum: Decoding the Pricey Realm of Palm Leaf Plate Manufacturers in the USA

Palm leaf plates, a popular eco-friendly alternative to plastic and paper plates, often come with a higher price tag in the USA. If you've ever pondered why Palm Leaf Plate Manufacturers in the USA are Expensive, this blog aims to unravel the underlying factors behind their elevated costs. From limited raw material availability to labor expenses, we will delve into the key reasons contributing to the relatively higher prices of palm leaf plates in the USA compared to countries like India. Let's embark on a journey to understand the elements that shape the manufacturing cost of palm leaf plates in the USA.

Raw Material Scarcity:

The restricted availability of suitable palm leaves for plate production is a primary factor driving up the costs in the USA. Thriving in tropical regions like Southeast Asia and India, these raw materials incur transportation and import costs, thereby contributing to the overall expenses and making Palm Leaf Plate Manufacturers in the USA expensive.

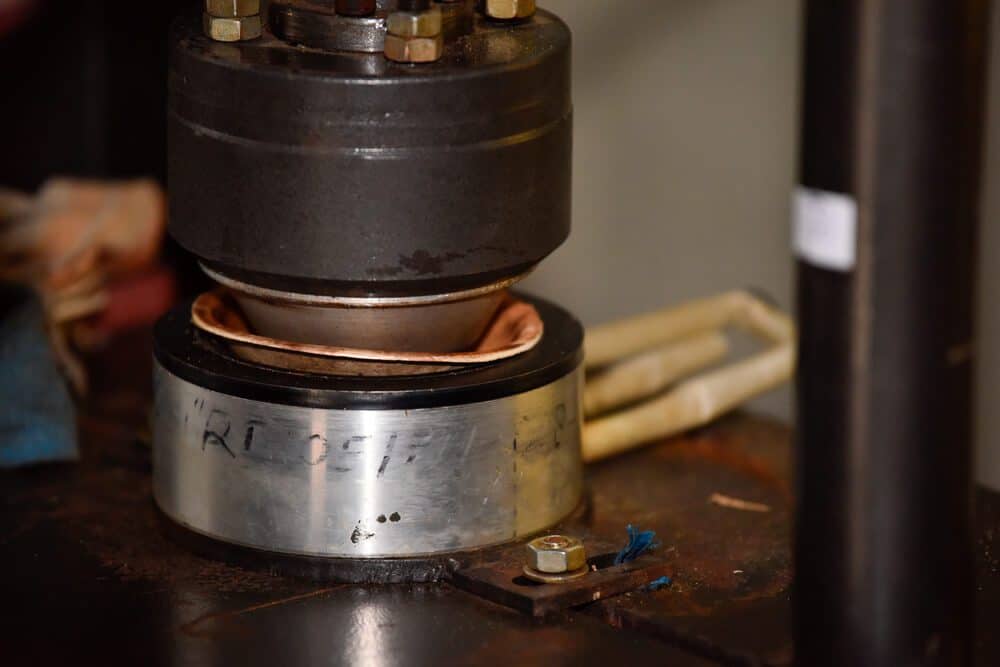

Machinery and Dye Dearth:

Importing the machinery required for palm leaf plate production, along with the associated dyes, is an expensive endeavor due to shipping costs and import duties. Furthermore, the absence of local machinery support and maintenance services amplifies the overall expenses. In contrast, India boasts a well-established market for machinery maintenance, support, and resale, rendering the manufacturing process more cost-effective.

Labour-Intensive Processes:

The production of palm leaf plates involves a series of labor-intensive steps, including sourcing, storage, display, buffing, segregation, and packing. Each stage demands hands-on work, making it time-consuming and labor-intensive. However, the higher labor costs in the USA contribute to Palm Leaf Plate Manufacturers in the USA being Expensive compared to countries like India. In India, laborers receive a daily wage of approximately 350 INR, equivalent to 5 USD for a nine-hour workday. In contrast, the minimum wage in the USA ranges from 8 to 10 USD per hour. This substantial disparity in labor costs directly impacts the overall expenses and contributes to Palm Leaf Plate Manufacturers in the USA being Expensive.

Waste Disposal Considerations:

Proper waste disposal is crucial in palm leaf plate manufacturing. In the USA, stringent waste disposal regulations and associated costs drive up overall production expenses. Compliance with environmental standards, waste management practices, and additional fees all contribute to Palm Leaf Plate Manufacturers in the USA being Expensive.

Water Usage Disparity:

Water plays a vital role in the manufacturing process of palm leaf plates, particularly in cleaning off the natural dirt and mud from the leaves. Freshwater availability and costs differ significantly between India and the USA. In India, freshwater is relatively more accessible and affordable compared to the USA, further amplifying Palm Leaf Plate Manufacturers in the USA being Expensive.

Conclusion:

The higher cost of palm leaf plates manufactured in the USA, in comparison to countries like India, can be attributed to various factors. Limited raw material availability, machinery and dye expenses, labor-intensive processes, higher labor costs, stringent waste disposal regulations, and water availability and costs all contribute to the relatively higher prices. Understanding these factors shows why palm leaf plates from the USA may come at a premium. Despite the elevated costs, the eco-friendly nature and unique aesthetics of palm leaf plates continue to attract environmentally-conscious consumers worldwide.

Q1: What factors contribute to the high prices of palm leaf plate manufacturers in the USA?

A: Several factors contribute to the high prices, including limited raw material availability, higher labor costs, machinery and dye expenses, stringent waste disposal regulations, and disparities in water availability and costs.

Q2: Are there cost-effective alternatives to palm leaf plate manufacturers in the USA?

A: Yes, alternatives such as bamboo or bagasse plates offer similar eco-friendly qualities at potentially lower costs.

Q3: Can I find palm leaf plate manufacturers in the USA who offer competitive pricing?

A: While prices may vary, there are manufacturers in the USA who provide competitive pricing. Researching and comparing options can help find the best deals.

Q4: Do higher prices for palm leaf plate manufacturers in the USA guarantee better quality?

A: Higher prices do not necessarily guarantee better quality. It is essential to assess manufacturers based on their reputation, certifications, and customer reviews.

Q5: Are there sustainable initiatives or government regulations influencing the pricing of palm leaf plate manufacturers in the USA?

A: Sustainable initiatives and government regulations focused on environmental preservation and fair labor practices can impact the costs associated with palm leaf plate manufacturing in the USA. Compliance with these standards may contribute to higher prices.